High Low Temperature Testing Chamber for PV Module

standard

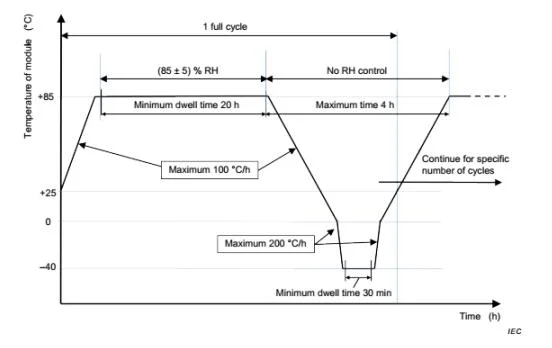

It's according to IEC61215,IEC61646,UL1703 standard requirement

purpose

It's to determine the ability of the module to withstand thermal mismatch , fatigue and other stresses caused by repeated changes of temperature

specifications

1.Temperature range:-40~85ºC

2.Temperature fluctuation:≤±1ºC

3.Temperature deviation:≤±1ºC

4.Temperature uniformity:≤±2ºC

5.Rise and down speed rate:satisfy IEC61215 standard requirement

6.Humidity range:30~98%RH

7.Relative humidity deviation:±%3FS, deviation 85±2%RH, 90±2%RH

8.Humidity fluctuation:±2%RH

9.Humidity uniformity:≤2%RH

10.Thermal cycle testing, module surface's temperature change rate should not more than 100ºC/h limit temperature the lowest maintain time is 10 min, one test is 200 times or 50 cycles

11.Placed 12 PCS test module

12.Inner chamber size approx:1.5×2.5×1.5m (L×W×H)

13.Outer chamber size:approx 2.5×3.0×2.5m (L×W×H)

14.Inner chamber material:stainless steel

15.Outer chamber material :stainless steel

16.Control system:automatic calculus

17.Display panel: Touch screen

18.Real-time curve show:can show program set time, adjust curve sample rate record cycle , show set value curve and actual running valve curve

19.Real-time set display: show perform program number, period of time , the rest of time and cycle times

, temperature value and humidity value

20.Communicate interface:RS-485 communicate interface, match on line software can connect to the computer , data save, print and download

21.Humanized operation interface automatic control:refrigeration compressor, automatic energy valve, temperature , humidity , electric heating, etc

22.Independent control:the program controller will heat up/humidification/dehumidification/cooling etc function complete independent control, save the energy

23.Language:Chinese and English , can change each other

24.Power down reset and power down memory function

25.Inner material:SUS # 304 high temperature resistant high tension stainless steel sheet

26.Outer material:Antirust steel plate+baking finish

27.Thermal insulation material:high density hard PU foam and glass insulation cotton

28.Refrigerant : adopt the newest HFC environmental protection refrigerant

29.Refrigerant valve:automatic switch regulating refrigerant valve

30.Power:380V 260HZ

Testing Machine images show

standard

It's according to IEC61215,IEC61646,UL1703 standard requirement

purpose

It's to determine the ability of the module to withstand thermal mismatch , fatigue and other stresses caused by repeated changes of temperature

specifications

1.Temperature range:-40~85ºC

2.Temperature fluctuation:≤±1ºC

3.Temperature deviation:≤±1ºC

4.Temperature uniformity:≤±2ºC

5.Rise and down speed rate:satisfy IEC61215 standard requirement

6.Humidity range:30~98%RH

7.Relative humidity deviation:±%3FS, deviation 85±2%RH, 90±2%RH

8.Humidity fluctuation:±2%RH

9.Humidity uniformity:≤2%RH

10.Thermal cycle testing, module surface's temperature change rate should not more than 100ºC/h limit temperature the lowest maintain time is 10 min, one test is 200 times or 50 cycles

11.Placed 12 PCS test module

12.Inner chamber size approx:1.5×2.5×1.5m (L×W×H)

13.Outer chamber size:approx 2.5×3.0×2.5m (L×W×H)

14.Inner chamber material:stainless steel

15.Outer chamber material :stainless steel

16.Control system:automatic calculus

17.Display panel: Touch screen

18.Real-time curve show:can show program set time, adjust curve sample rate record cycle , show set value curve and actual running valve curve

19.Real-time set display: show perform program number, period of time , the rest of time and cycle times

, temperature value and humidity value

20.Communicate interface:RS-485 communicate interface, match on line software can connect to the computer , data save, print and download

21.Humanized operation interface automatic control:refrigeration compressor, automatic energy valve, temperature , humidity , electric heating, etc

22.Independent control:the program controller will heat up/humidification/dehumidification/cooling etc function complete independent control, save the energy

23.Language:Chinese and English , can change each other

24.Power down reset and power down memory function

25.Inner material:SUS # 304 high temperature resistant high tension stainless steel sheet

26.Outer material:Antirust steel plate+baking finish

27.Thermal insulation material:high density hard PU foam and glass insulation cotton

28.Refrigerant : adopt the newest HFC environmental protection refrigerant

29.Refrigerant valve:automatic switch regulating refrigerant valve

30.Power:380V 260HZ

Testing Machine images show